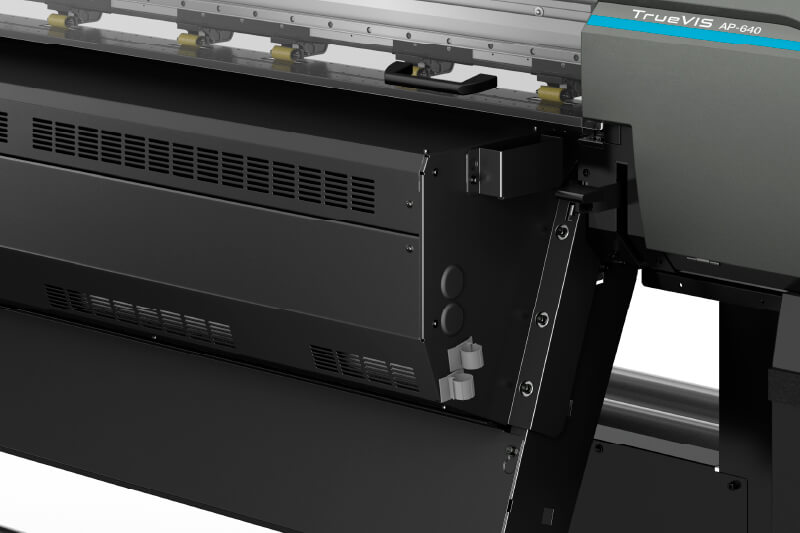

Do More with Resin Printing

The TrueVIS AP-640 redefines resin printing with high colour saturation on a wide range of materials. It features new TrueVIS resin ink and advanced machine features to optimise colour reproduction and expand your graphics to include a wide range of applications.

Putting Quality First with Clean and Safe Resin Ink Printing

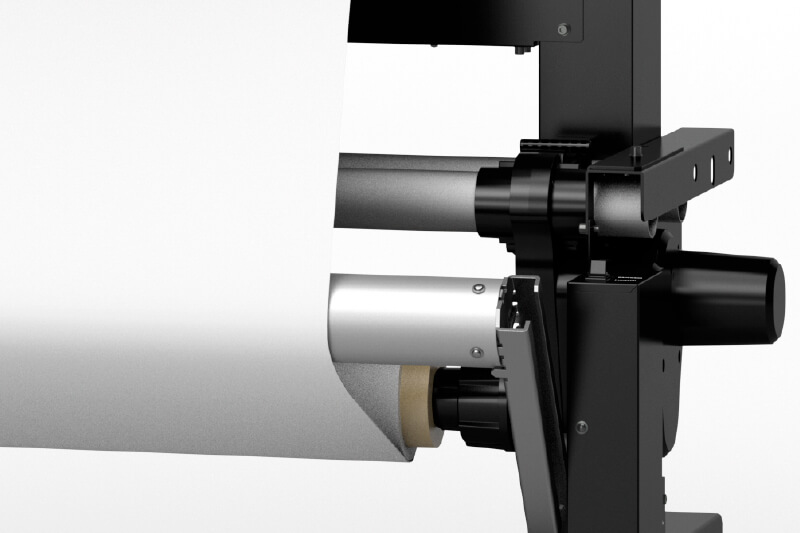

Premium Roland DG Resin Ink

TrueVIS Resin Ink

The highly concentrated colour pigmentation enables heavier saturation than conventional resin inks for optimum impact on paper, fabric, canvas, wallpaper, non-PVC materials, and other media.

Prioritizing Safety

TrueVIS Resin inks are GREENGUARD Gold certified, meaning they meet strict standards of low chemical emissions making them ideal for indoor applications.

True Rich Color

The True Rich Color preset takes full advantage of the high colour saturation of new TrueVIS Ink to maximize vibrancy and ensure neutral greys, smooth gradations, and natural skin ones.